Making payment easy for customers is massively important to the success of a car wash, and being able to break bills and make correct change is crucial to that process. Standard Change-Makers is a leading equipment manufacturer offering those solutions, and that’s why they have been an important partner of Kleen-Rite since the late 1980s.

History of Standard Change-Makers

Standard offers machines with everything from simple functionality that provides coin change, to more sophisticated transactions like starting a car wash, credit card acceptance, and cellular signal processing. Their strong reputation is based on the security of their cabinets and the longevity of their products. Their units boast heavy gauge steel cabinets with solid weld lines, steel housing hoppers, and metal gears. It’s not unusual for their machines to be in service for 20+ years and have millions of cycles on them – you can find plenty of them still in use that fit this description! Payment convenience for customers, reliability of products, and trustworthiness are what Standard Change-Makers is all about.

Standard was founded in 1955 by James McNutt, Sr. It was an affiliate of Nik-O-Lok, which at the time was the world’s largest coin-operated lock manufacturer. Charles Van Cleave, McNutt’s grandfather, founded Nik-O-Lok in 1910. The two companies operated out of the same facility in Indianapolis, Indiana. Standard became a separate corporation in 1965, and Nik-O-Lok eventually became a division of Standard. Both are still in operation today as privately held corporations.

Early History

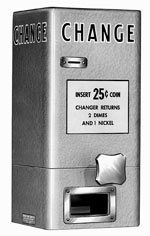

Early on, Standard was manufacturing machines in an upstairs room at Nik-O-Lok in downtown Indianapolis. About a year into their existence, technology was introduced that allowed for a new series of machines that could change out the popular half-dollar coin (and the silver dollar coin, in some cases). This was very advanced for the vending industry, as past machines could not accept coins of that size. Coin laundromats started to appear around the U.S.A. and Canada, providing another application where Standard’s durable changers were ideal.

The next major step for the company came in 1964 with technology for another type of money acceptance – the $1 bill. Standard worked with outside companies that provided these innovative bill validators for their change machines. In the same year, Standard added additional manufacturing space a short distance from the original facility. By 1978, Standard’s machines were accepting $5.00 bills.

More Recent History

Yet another revolutionary year in Standard history was 1987, when the company introduced their System 500 bill acceptors. Part of an initiative to have control of their acceptor technology instead of relying on outside parties, these validators accepted $1, $5, $10, and $20 bills. This was a first in the industry, and some industry analysts even criticized the move because they didn’t think customers would ever want to change a $20 bill.

Standard added a third location in 1988, but it wasn’t the most efficient way to operate. Between 1991 and 1992, James McNutt Jr. spearheaded the build of a modern 67,000 square foot building to house all operations and manufacturing, and it’s still their headquarters to this day.

Standard moved through the 90s with expansions into Mexico and South America, and expansions to their product lines. Important product introductions included the System 600-FST, a line of fraud and theft-deterring acceptors, and their Bill-to-Bill Exchanger that broke large bills into smaller bills. The early 2000s saw the emergence of their Modular Smart Hopper technology, EASYPay, and Guardian XP. From 2017 to 2019, Standard released their Glory Dispensers, EF+ Modules, SC-Conversion Kits, and MC400RL-SLIM.

Standard Change-Makers Now and in the Future

The McNutt family owned and operated the company for several decades, with both James Sr. and Jr. taking turns at the helm. In 2021, Rob and Kathleen Unterborn of RKU Standard Incorporated purchased the company. They maintain the family-owned focus and adhere to the traditions set forth by the McNutt family.

Standard still focuses on constant, smart improvement of their products. For example, they recently had some complaints about their T-handles requiring a lot turning and time to open, which was especially cumbersome on two-lock doors. They introduced a three-point locking system that eliminates turning without sacrificing security.

Like most companies, they are also working hard to reduce their lead times and catch up on backlogs related to current supply chain and labor issues. They hope to return to their 2 to 3-week ARO shipment schedule that they had pre-COVID.

Of course, they still have an eye towards new technology and advances in the industry. Although still early in development, they introduced their EF-Touch Module at the Nashville ICA Show. Instead of a 2-line LCD display, the new module has a 7” touch screen interface. The screen is similar to an interactive phone or device that is icon-driven and very user-friendly, making it easier for customers to get the most out of their machines.

Unlike many competitors, Standard Change-Makers has an in-house engineering team, builds their own cabinets, and produces their own electrical component assemblies. This commitment to high-quality production is why Kleen-Rite is proud to work closely with Standard, and looks forward to many more years of success together!

Thanks to Mike Coons, VP of Sales and Marketing at Standard Change-Makers, for providing information for this piece.