Kleen-Rite held a series of educational seminars called the “Car Wash Operator Master Class: Your Tools for Success!” This completely free event was held on November 13th, 2019 at the Kleen-Rite location in Grand Prairie, TX and featured a variety of topics including drop shelf vending, pump troubleshooting, self-serve chemicals, credit card acceptance, video surveillance, and in-bay automatic chemicals. There was also a free lunch and complimentary networking cocktail hour. The In-Bay Automatic seminar was presented by Randy Donatelli, a Regional Sales Manager for Simoniz USA, Inc. Donatelli’s seminar was packed with valuable information about the chemicals used in both friction and touch-free washes –the two main types of in-bay automatic car washes (IBA).

FRICTION IN-BAY AUTOMATICS

Friction Is Key, But Chemicals Are Still Necessary

In-bay friction machines rely heavily on mechanical action to perform the cleaning of the vehicle. As the name suggests, the car wash brushes actually contact the vehicle surface to remove dirt and residue. Proper lubrication is needed to avoid damage from that contact. Although the mechanical action is very important, you still need chemicals to get the cleaning process moving. For example, a high pH presoak is still necessary to help loosen the road film on a car. Triple foam can be used as a conditioner or a polish depending on the application.

Friction In-Bay Automatic Programming

The list below includes the most commonly programmed services at friction car washes. These services are generally offered in packages that start on the low end with just a couple products, and build to the highest-priced package including every programmed option.

- Presoak (high Ph)

- Brush lube (low Ph, or Neutral)

- Triple foam

- Rinse

- Clear Coat or Hot Wax

- Dry agent

- Spot Free Rinse

- Drier

TOUCH-FREE IN-BAY AUTOMATIC

Water

Water quality is obviously important in every kind of car wash, but it’s even more significant when it comes to a touchless in-bay automatic. Water hardness measures the amount of calcium and magnesium salts in your water (using grains as the unit of measurement). Hard water has the ability to neutralize surfactants in detergents and weaken chemical effectiveness by up to 5% for every grain of hardness. Hard water can also clog injectors, check valves, lines, nozzles, and other parts in your system. Soft water will produce a richer lather and extend the life of your reverse osmosis membranes.

What level of water hardness is acceptable? The goal should always be to have zero grains, but one or two grains is okay. If you expect to deliver the best wash possible, you simply have to get your water to these low levels of hardness. Unless you have a direct source of incredibly soft water, which is very rare, you will need a water softener to treat all of the water being used in your touch-free wash.

Totally dissolved solvents (TDS), also known as spot-free water, is another aspect of car wash water purification. Although important to any car wash system, TDS is specifically pertinent for a touch-free in-bay automatic. This process of removing all minerals from your water is done with a reverse osmosis (RO) system. Dirty water is reclaimed and purified to be used again in things like a high-pressure rinse or undercarriage cleaning. Getting your water as pure as you possibly can is crucial to properly rinsing the vehicle without leaving unattractive water spots and residue.

As a note, a RO system can be used to remove water hardness along with other minerals. It’s still recommended that you use a water softener in addition to your RO, as water hardness will plug up RO membranes. That means you’ll be replacing membranes at a faster rate. You may also see a dip in performance in your RO system when it comes to removing other minerals, resulting in water that spots. It’s best to simply add a water softener as the first stage of the purification process. Chlorine will also quickly degrade your RO membranes. To avoid this, use a carbon filter to be used before the RO process.

TDS is measured in parts per million (ppm). As a rule of thumb, water under 50 ppm will not spot. This can be tested with a TDS meter either at the RO tank or right in your in-bay automatic bay. It’s recommended that testing be done in the bay as this is the true test of what your customers are getting in their wash. If you only test at the RO tank, another problem may occur further downstream that causes purity issues that you won’t detect.

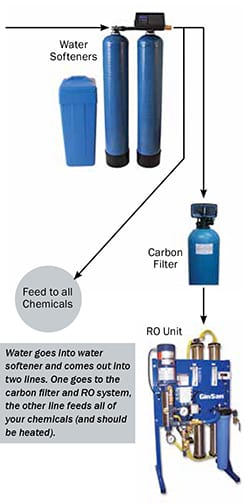

The below image illustrates the ideal plumbing for an in-bay automatic wash, as described above.

Service and Dwell Time

Touch-free in-bay automatic equipment has become faster and faster over the years. The trend in the industry has been to drastically cut down on the amount of time that a customer spends in the bay. Customers expect a speedy process, and operators want to send as many cars though the bay as possible. Donatelli has even experienced situations where customers exited a bay mid-wash because they thought a slight delay in the process meant that something had gone wrong. In fact, the wash was just programmed to give detergent time to work. This standard of having exceptionally fast washes means that chemical strength is relied upon as much as –or even more than– the dwell.

At the same time, chemical strength has its limits. Dwell time is still very important to achieving a proper wash. Allowing a delay so chemicals can sit and break down dirt is still a part of the process that operators have to account for, even if it means more service time and fewer cars through the bay. The quality of the wash is ultimately the most important aspect of running a successful touch-free IBA with a solid reputation.

Donatelli has a simple but apt comparison to illustrate the value of dwell time. When you have a casserole dish with baked-on gunk, you throw some degreasing dish soap on it and let it sit in the sink for ten minutes. After that, the residue comes off easily. The concept is the same for dwell time, and it actually ends up being a more cost-effective solution than trying to blast the car with stronger chemicals. The longer any solution can rest on the surface being cleaned, the better it will perform.

Temperature

Donatelli is frequently asked if heating water is necessary for car washes. He responds to that question with his own: “Do you use hot or cold water to wash your hands?” The answer, for most, is hot. That’s because the hot water actually opens up the pores on your hands to get a deeper clean. Heated water works in much the same way on a vehicle’s surface, opening the porous clear coat and paint to release dirt and particulates that have become trapped in the surface. That means it’s especially important to use hot water with detergents to get a better clean.

The ideal temperature for detergents is between 110 and 140° Fahrenheit, with 120° Fahrenheit being optimal. Anything hotter than that may damage equipment or wear out seals at an excessive rate.

Operators should remember that outside temperature does affect cleaning. The hardest time to clean is after rainy or cold weather. This is when hot water is most useful in detergents. Cold temperatures lock in dirt, and heated detergents must be used to really open up the vehicle surface and loosen those materials.

On the other end of the thermometer, excessively hot temperatures can cause soap to dry on the surface before it can be rinsed. In this case, a pre-rinse is necessary to soften the vehicle surface. Warmer temperatures can work in your favor by allowing the vehicle to dry faster. Conversely, cold weather may prevent water from beading, so it will lay on the surface and dry much slower.

Mechanics

A vast majority of the time when customers contact Donatelli thinking they’re having an issue with a chemical, it can actually be traced to something mechanical in their system. Once he goes through his troubleshooting process, it’s nearly always something like a bad injector or a malfunctioning solenoid causing the customer’s problem. These issues often wreak havoc with the dilution rate. At the wash stage, these equipment problems can make it appear as if a chemical was not manufactured properly or has gone bad. In reality, that’s rarely the case.

Donatelli points out that Simoniz chemicals are mixed in huge vats in very large amounts; often 20,000 gallons or more per batch. In the manufacturing process, everything is measured very carefully, and the chemistry is one of the more consistent things you have at your car wash.

Sometimes, there is a misconception with touch-free cleaning that the chemistry does all of the cleaning work. Operators must be aware that chemicals only serve to loosen and break up road film, while a high-pressure rinse is still the thing that actually removes the material. It’s extremely important to maintain powerful, consistent pressure levels when rinsing a vehicle. In other words, a chemical should not immediately be blamed for poor performance if you don’t have an ample rinse accompanying that chemical application.

Touch-Free In-Bay Automatic Programming

Similar to friction bays, touch-free washes offer a variety of different cleaning products to customers. Again, they’re typically grouped in packages ranging from a basic wash to a complete premium wash experience. The list below contains the options typically programmed in a touch-free in-bay automatic.

- Soap 1 (low Ph)

- Soap 2 (high Ph)

- Dwell

- HP Rinse

- Hot Wax

- Triple Foam

- Drying agent or Clear Coat

- Spot Free Rinse

- Drier

IN-BAY AUTOMATIC CHEMISTRY

pH Scale

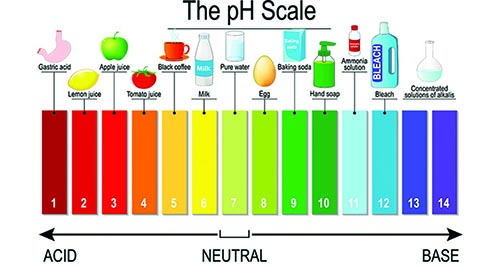

The pH Scale is a one-to-fourteen numerical scale that determines if a chemical is an acid, a neutral solvent, or an alkaline. Pure water is the most neutral substance and has a pH directly in the middle of the scale at seven. Anything below seven is more acidic, with a one pH substance being the most acidic. Anything above seven is an alkaline (also known as a base), with fourteen being the highest pH alkaline.

Donatelli stressed that the pH Scale does not dictate the concentration or actual strength of the chemical being tested. For instance, if a detergent has a pH of thirteen, that does not mean it’s more concentrated than a chemical with a pH of twelve. The thirteen only signifies that it is a stronger base than the pH twelve product.

Single-Step vs. Two-Step (One-Product vs. Two Product)

Generally, there are two different approaches to offering soap services in an IBA. The single-step method uses just a high pH soap. This means you only have to purchase one soap for the presoak process. Although there is only one soap used, there are usually two or more passes made with the product to ensure thorough application.

The two-step method uses both a low pH and a high pH soap. When the two-step method is properly done, the low pH solution is used first to cool the vehicle’s surface and reduce the chances of chemically flashing the paint. After that, the high pH soap is applied to further loosen and break up dirt.

Titration

Titration is a process used to test the strength or dilution of a chemical. For an acid, you add an alkaline until the solution is neutral. By keeping track of how much alkaline is added, you can determine the dilution rate of the acid. Titration kits are available to make this testing process very easy. These tests should be done with some regularity at your wash to ensure that all chemicals being distributed are at the correct strength.

Thanks to Randy Donatelli for his excellent presentation at Kleen-Rite’s first Master Class. Keep an eye out for future Master Class events organized by Kleen-Rite! And don’t forget, the Kleen-Rite Learn More, Earn More Expo in November 2020 will also have a variety of valuable seminars from industry experts!