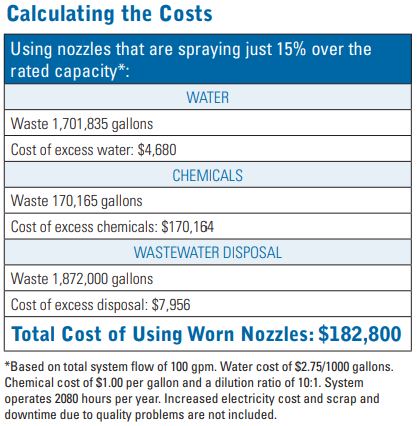

Believe it or not, using worn spray nozzles is washing profits down the drain. According to a study by Spraying Systems, damaged nozzles could potentially cost you up to $182,800 a year! Imagine the impact of these losses on small businesses, startup car washes, and even large chains operating with tight profit margins. With that alarming statistic in mind, you might ask yourself, “How do I tell if a spray tip is worn and costing me money?” In this guide, you will learn how to spot spray nozzle wear at your car wash and the negative impact a worn nozzle has on your bottom line.

Impacts of Worn Spray Nozzles on Your Bottom Line:

Worn nozzles or spray tips lead to uneven and inefficient spray patterns. Though it may seem minor, nozzle wear can substantially impact costs. As nozzles degrade, they require more water and chemicals to achieve the same cleaning power, leading to wasted resources and increased expenses. The more a nozzle wears, the greater the waste, ultimately affecting the bottom line. For operators, regularly maintaining or replacing nozzles can be a straightforward yet effective way to control expenses. Spraying Systems Co. even offers a cost-savings calculator to help operators see the financial impact of worn spray tips and what you can save by replacing worn ones.

The Importance of Routine Spray Tip Inspections:

Like any product, the more you use a spray tip, the more wear it will sustain. As the orifice ages, its opening will erode, causing the flow rate to increase and pressure to drop. You may think it is your pump. However, the flow rate does not correlate with the supplied pressure in systems with positive displacement pumps. Therefore, when the orifice wears, the pressure drops because more liquid can move through the tip. Routine nozzle checks should be standard practice for car wash operators, as early signs of wear can indicate inefficiencies.

The Red Flags of Spray Nozzle Wear:

There are common indicators that spray tips are wearing out and losing efficiency. Knowing how to recognize these signs will help you identify worn spray tips so you can remove them from service and replace them with a new one.

Change in Flow Rate:

Like any product, the more you use a nozzle, the more it will wear. As the orifice ages, its opening will erode and widen, causing the flow rate to increase. The flow rate does not correlate with the supplied pressure in systems with positive displacement pumps. Therefore, when the orifice wears, the pressure drops because more liquid can move through the tip.

Increased Chemical and Water Use:

Another sign of spray nozzle wear is increasing monthly chemical and water consumption. This is due to the increase in flow rate as the orifice enlarges due to wear. An increased amount of water and stronger chemical dilutions will be necessary to achieve the same results resulting in higher water bills and more chemical orders throughout the year.

Increased Droplet Size:

You can’t see the droplet size change. However, you will be able to tell based on other changes. For example, when the orifice grows, the flow will increase, causing pressure to drop resulting in larger water drops. As the drop size increases, the area covered decreases.

Irregular Nozzle Spray Patterns:

As the orifice wears, the spray pattern deteriorates. It is important to note each type of nozzle will show a different variation in the spray pattern. Hollow cone nozzles will lose uniformity and develop streaks. When the flat fan and full cone nozzles degenerate, more liquid will flow down the stream’s center, decreasing coverage.

Signs of Irregularity Based on Spray Pattern Type:

- Flat Fan Spray Pattern: Watch for heavier flow in the center of the spray pattern and reduced coverage.

- Full Cone Spray Pattern: This type will show a higher concentration of liquid flowing toward the pattern’s center.

- Hollow Cone Spray Pattern: These tips will produce streaks in the circular spray ring pattern or changes in flow rate.

Decreased Spray Pressure and Lower Impact

Pressure will decrease as the orifice wears out, reducing the cleaning power of the spray tip. This decreases cleaning quality, leaving missed spots on vehicles that aren’t cleaned thoroughly. Additionally, when used with a centrifugal pump, the reverse may occur. The impact of the nozzle may increase, which is bad if it becomes too strong for its purpose.

Additional Symptoms:

Other symptoms may be easier to spot. Inspect the spray tip for any noticeable damage from impact and evidence of the material softening or weakening. Leaks around the tip are a big red flag.

Reduced flow rate, spray angle, or spray pattern may also indicate you need to clean the orifice. Proper maintenance is important. If you see any of these indicators, try cleaning the tip before replacement. Use non-abrasive cleaners or solvents to clean the orifice and internal components to see if removing clogs or scaling can solve the issue before buying a new spray tip.

If you determine a new spray tip is needed, the next step is to choose the right one for your needs.

How to Choose the Right Spray Tip?

There are many factors to consider when purchasing spray tips.

Choose The Correct Material:

First, identify the spray tip material that best suits the intended use. Many car wash applications may require special materials to endure the chemicals utilized to clean cars. Spray tips are available in a variety of materials. The most common are brass, stainless steel, and PVC (plastic). Each of these materials has advantages and disadvantages in different operating conditions.

Pick the Right Spray Angle:

Next, decide on the ‘degree of spray’ or spray angle you need. This will depend on what or how you are cleaning. The most common angles for our purposes are 0°, 15°, 25°, 40°, and 65°.

- 0° – This cutting nozzle is never used for car wash applications. It delivers a thin, concentrated stream that can gouge or cut stubborn stains from hard surfaces. This stream can cause damage to softer surfaces and strip paint. It’s ideal for cleaning cracks and crevices, including removing stains and adhesives, but should only be used carefully on hard, durable surfaces.

- 15° – This chiseling tip is meant to be directed at a 45° angle to surfaces. The stream acts like a scraper to prep surfaces. It’s also great for cleaning stubborn bug guts from vehicles with caution.

- 25° – Used as a flushing nozzle, this tip produces a brush-like spray that “wet-sweeps” debris like leaves and mud from surfaces. These are ideal for areas like truck beds and construction vehicles.

- 40° – Versatile car wash spray tip with a wide, uniform spray that can cover a large area quickly. This nozzle is safe for the most common surfaces and car wash applications, plus surfaces often cleaned in pressure wash applications.

- 65° – The soap nozzle has a larger orifice and is used to apply soaps, detergents, and other thicker liquids at low pressure. The wide spray pattern and gentler spray deliver better coverage.

Identifying the Correct Spray Tip Size:

When replacing a worn spray tip, ensure the new one is the same size as the original. Looking at a spray tip, you will find a 4-digit stamped number somewhere on the part. These are standard on most spray tips. The first two digits indicate the spray angle or degree of the tip. The last two numbers designate the orifice size which correlates to flow rate. Some may also include letters to indicate the material.

How to Monitor Nozzle Performance:

You can monitor spray tip performance by using a beaker test. Set up an examination procedure that you can repeat regularly and record the results.

Here is an example of a test to record nozzle performance. Place beakers or tubes under the nozzles as shown in the video of an assessment conducted by spraying systems. Purchase glass tubes with markings to help you measure and document the level of fluid they collect.

After installing a new nozzle, document the performance and use the initial result as your base. Then compare it to the results of each consecutive test. You should notice a difference over time.

Develop an assessment schedule to help you detect waste before it impacts your profits. A great time to record nozzle performance is during routine maintenance shutdowns.

Final Thoughts:

Detecting nozzle wear is crucial to your success, as customers will notice streaks on their vehicles and other cleaning inconsistencies after a wash. By identifying the signs of a worn spray tip, you can replace it, reduce costs from wasted water, and ensure customer satisfaction. The sales team at Kleen-Rite is ready to assist you in choosing the right spray tips for your needs. If you have questions or need recommendations for specific applications, feel free to call or use our online chat. We’re here to help you get exactly what you need!

This post was last updated on 1/2/2025.