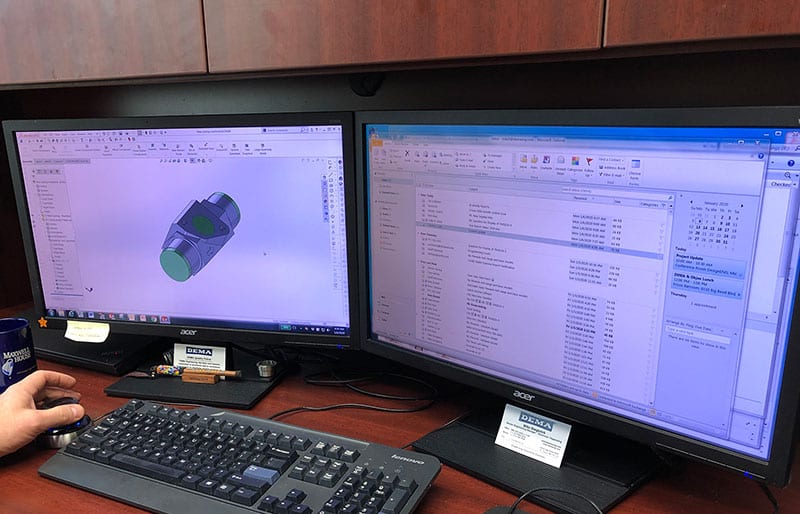

The Rocket Injector from DEMA combines decades of venturi injector expertise and car wash industry knowledge. DEMA has developed a revolutionary new way of delivering chemicals in car wash and pressure washing applications. The innovative design is the brainchild of a DEMA engineer with years of real world experience with several car wash manufacturers. DEMA combined that industry knowledge, current trends in the car wash industry, and their own design expertise. The result? Modern venturi injectors that are the most efficient, most user friendly, and most versatile injectors on the market.

Most Efficient Injector on the Market

The Rocket injector enables cleaning at greater pressures while using less raw chemicals. It accomplishes this through the use of an efficient design that requires a lower pressure loss. In turn, this allows for a chemical delivery system with a lower total pressure, that still achieves the desired application pressure. Running at a lower pressure means less wear and tear on all the components of the wash. This leads to less overall maintenance and better performance. No competitive injector can claim the same level of low pressure loss.

Service-Friendly Injector Design

Use of a removable nozzle and metering barb make maintenance and repair of a Rocket injector simple. With a Phillips head screwdriver and an Allen wrench, the unit can be torn down to all its components, cleaned out, and repaired if needed. DEMA understands that with simple maintenance and service, the rocket extends the overall life of a chemical delivery system. That’s why we designed the long lasting, durable injector bodies to be field serviceable. This reduces the cost to maintain any chemical delivery system when utilizing the Rocket. All this leads to a lower cost of ownership for chemical delivery.

Versatility in Design and Application

The Rocket leads the industry by covering the extreme ranges of both chemical types and dilution ratios needed by the car wash operator. The flexibility of the Rocket helps to operate systems at lower pressures which saves energy and reduces operating costs. The Rocket gives the car wash owner the greatest range in pressure, dilution, and chemical compatibility which makes it the most adaptable injector on the market.

What We Have Learned

Over the last 5 years, Rocket usage in the car wash industry has taken off. More and more car washes are turning to DEMA and the Rocket to meet their chemical delivery needs. Rocket is the high performance injection technology propelling the future of chemical injection systems. It puts control back in the hands of the car wash owner and operator and made chemical injection simple to understand and easy to dial in.

The Rocket injectors come equipped with Aflas seals as a standard. Except for the nozzle, all wetted parts of the injector are polymer based. The nozzle itself is 316 series stainless steel. This has proven to be the most chemically compatible set up in the industry. Kits are available for changing the injector seals for compatibility with specific chemicals. Two kits, one EPDM and one Viton, are available as replacements for all three seals inside the units.

Improvements and Rocket 2.0

Through working with chemical companies in the car wash industry, DEMA has created industry leading chemically compatible material designs for critical components on the injector. DEMA has been working on developing and releasing the newest all composite polymer nozzles. These take the most chemically resistant injector on the market, and ratchets up the compatibility. The new polymer nozzles are made from a material with no known chemical solvents. After successful field testing, DEMA has decided the new nozzles are ready to go to market. These new nozzles will be available on all standard Rocket injectors in early 2020.

This project is an example of the importance of trusted relationships within the industry. DEMA worked with valued partners in the car wash industry, both on the chemical and equipment sides of the business. They evaluated the harshest chemicals being used today, as well as the worst water quality. Both led to improvements of the nozzle so that it can still work with poor quality water and in extreme chemical situations.

Another development that is in the works is for larger sizes injectors to handle higher flow rates and larger volume wash applications. This is an expansion into the larger vehicle and large volume applications that DEMA had previously utilized their older technology. Look for new Rocket 2.0 injectors coming out that handle flows up to 14 GPM or more.

For more information on our Rocket injectors or any of the improvements that are coming for the Rocket, please feel free to reach out to a DEMA regional sales manager.