If you’re a new owner of a car wash or a pressure washing business then you’ll want to learn the attributes that are important when buying spray guns. Even if you’re a seasoned operator, you might want a quick review of the relevant information needed when purchasing guns. Like most car wash equipment, finding the perfect product might require some trial and error. Understanding the basic specifications can make that search much easier!

High-Pressure Washer Gun Attributes

PSI (Pounds per Square Inch)

One of the more important details that you’ll want to pay attention to when buying spray guns is the pressure rating. Determine what you need for your guns will first require you to know the pressure levels in your high-pressure system. Car wash owners should select their equipment based on business volume, property size, and services offered, to name a few. Professional pressure washers might consider the size and scope of their jobs, business volume, and ability to transport.

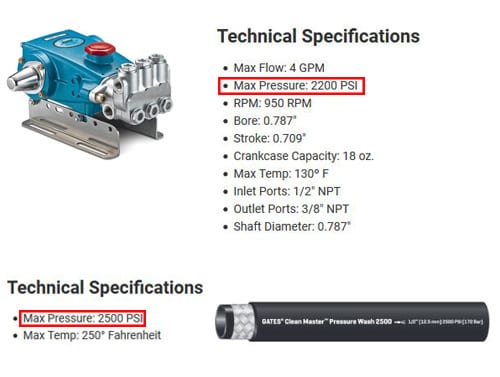

You’ll always want your tools and accessories to be rated for AT LEAST the maximum pressure of your pumps. This is a basic but key concept when it comes to high-pressure systems. For example, you don’t want to use a hose with a lower maximum pressure rating than the amount of pressure being generated by your pump. Same idea with spray guns; you’ll want to know the maximum rating of a gun. To establish a bit of a safety buffer, consider getting a gun with a pressure rating about 10% higher than the maximum pressure of the pump.

If there is too much pressure for your gun to handle, you’ll constantly be replacing parts and seals – and that’s if the gun isn’t damaged beyond repair. You’ll have to deal with guns that don’t perform properly. You might even face unsafe situations if intense pressure causes accidents while the gun is being used. In some cases, pressure spikes can also harm pumps.

In addition, don’t ignore the minimum pressure rating on a spray gun. If the pressure in your system dips below a certain level, some guns are not designed to function at a very low pressure. Customers and employees may become confused and frustrated if a spray gun suddenly stops performing.

Note: Pressure is also commonly measured in “bars”.

GPM (Gallons Per Minute)

GPM is used to measure the flow rate of a gun. This is the maximum amount of water that can safely exit the spray gun. Like pressure rate, you will want the flow rate of your spray gun to correspond to the flow rate of your pump. This ensures safe, consistent operation and avoids damage to the gun.

Note: Flow rate is also commonly measured in “Liters per Minute”.

Inlets and Outlets

The inlet and outlet on a spray gun are the connection points for hose and wands/lances with fittings on them. Three things are important with inlets and outlets: the numerical measurement, the type of thread, and the gender. When comparing connection points and fittings, the measurement should match, the thread type should match, and the genders should be opposite. For instance, if you have a hose with a 3/8” Male NPT fitting, your spray gun should have a 3/8” Female NPT inlet.

There are several different kinds of threads available in the industrial realm. Some of the most common options include: NPT, BSP, JIC, and Pushlock.

Maximum Temperature

The maximum temperature rating of a spray gun simply tells you the specific limit of how hot the medium can be when running through the gun. If you go beyond that point, the gun can become damaged and stop working properly. Inner component and handle material determine the maximum temperature of a spray gun. For instance, a spray gun using a stainless steel valve seat would likely have a higher temperature tolerance than a gun with a plastic valve seat.

Once you’re aware of the temperature levels of the medium being circulated in your high-pressure system, you can narrow down your spray gun search to the models that fit your temperature criteria.

Weep vs. Non-Weep

The primary factor that determines if you need weep or non-weep guns is climate. Weep guns have a small orifice in the bottom of the gun that allows a constant low-pressure flow of fluid to escape. This helps avoid freezing within the system and gun, even when not pulling the trigger. Non-weep guns completely shut off any water flow when you disengage the trigger. If you’re in a warmer climate, you can safely use non-weep guns.

For a more detailed discussion on weep versus non-weep guns, CLICK HERE!